If you want to repair the analog sticks on your PS4 or PS5 controller, the Hallstick installation is the perfect solution to fix and permanently prevent stick drift. Hallsticks use Hall-effect technology that works without mechanical friction, which significantly extends the life of your analog sticks and enables more precise gaming. In this detailed guide, we’ll show you how to install your Hallsticks yourself, solder them correctly and then calibrate them to make your controller like new again. The installation of TMR Hall sticks is exactly the same as that of normal Hallsticks.

We use special tools and high-quality materials that you can easily order via our website. We also give you tips on optimal cleaning and fine-tuning so that your controller works perfectly. At the end you will also find crosslinks to other cool modifications such as easy-to-install paddles, mod kits or our case configurator, which you can use to customize and improve your PS5 controller.

Step 1: Preparation – opening the controller and removing the circuit board

To begin with, you must of course open your controller and remove the circuit board. This is the basis for the Hallstick installation and should be done with care so as not to damage any components.

- Carefully open your PS4 or PS5 controller with a suitable screwdriver.

- Remove all screws and lift off the upper half of the housing.

- Carefully pull out the circuit board on which the analog sticks are mounted. Unsolder the cables from the adaptive triggers and the vibration motors.

- Clamp the circuit board in a circuit board holder so that it is stable while you work.

Our circuit board holder makes work much easier and ensures greater precision when soldering. If you don’t already have one, we strongly recommend that you use one to prevent damage to the circuit board.

Step 2: Get the right solder and tools

The right solder and tools are crucial for the Hallstick conversion. We recommend solder paste with a melting temperature of 181 °C. This low melting temperature reduces the heat effect on the circuit board and makes desoldering the defective analog sticks much easier and safer.

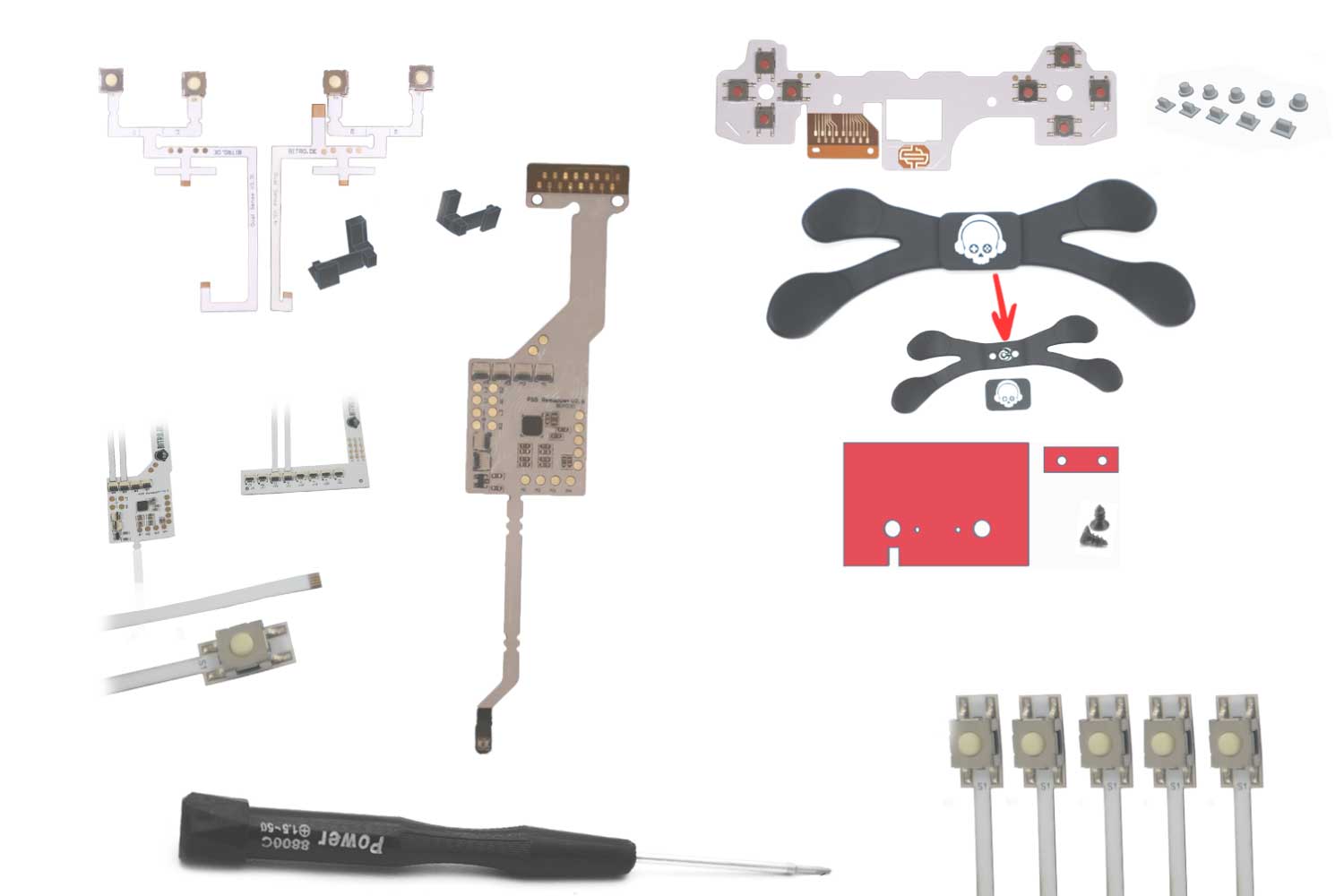

You also need:

- Our desoldering adapter for all soldering irons, specially developed for desoldering analog sticks. The adapter fits perfectly on the back of the sticks and enables quick and even heating.

- A professional desoldering pump to reliably remove excess solder.

- Standard Hallsticks or TMR Hallsticks

- 181 degree solder

- A powerful soldering iron with at least 80 watts of power. We recommend 100 to 120 watts to deliver the required heat quickly and constantly.

- Toothbrush and pure alcohol to clean the circuit board after soldering.

This combination of tools and materials is ideal for carrying out Hallstick installation professionally and safely.

Step 3: Apply solder to the soldering points

Before you remove the old analog sticks, you should apply a little of the special soldering paste to all soldering points. This ensures that the melting temperature of the existing solder on the circuit board is lowered and everything mixes better.

Proceed as follows:

- Use the dosing syringe to apply the 181 degree solder to each soldering point on the analog sticks.

- Spread the solder evenly so that all joints are well wetted.

The lower melting temperature means you can desolder the sticks more quickly and avoid damage to the circuit board due to excessive heat.

Step 4: Desoldering the old analog sticks with a desoldering attachment and soldering iron

Now comes the most technically demanding step: desoldering the old analog sticks with stick drift. To do this, place our special desoldering attachment on the circuit board at the soldering points of the analog sticks and heat up the soldering points.

This is how you proceed:

- Set your soldering iron to approx. 400-450 °C. This temperature is ideal for heating the solder joints quickly and safely. Allow the adapter to heat up briefly for 1-3 minutes.

- Place the desoldering attachment on the soldering tip and hold it on the back of the analog stick where the soldering points are.

- Hold the tip to the soldering points for approx. 30 seconds to a maximum of 1 minute until the solder becomes liquid. Now you can simply pull out the old analog stick modules.

- Then use the desoldering pump to suck the liquid solder out of the holes. You should use a normal soldering tip with a diameter of approx. 2.5mm.

If the desoldering pump no longer sucks properly, it may be clogged. Briefly heat the tip again and press the pump through once to clean it.

If solder residue remains in the holes on the circuit board, apply some more solder paste, heat the area again and vacuum the solder off again. This will clear the holes completely.

Step 5: Clean the circuit board thoroughly

After desoldering, there is often a lot of solder residue and dirt on the circuit board. This residue can cause problems later when soldering the new Hallsticks. This is why you must clean the circuit board properly after desoldering the defective analog sticks if you want to install Hallsticks that work perfectly and for the long term.

Therefore, clean the circuit board thoroughly:

- a toothbrush and pure alcohol (99% isopropanol)

- alternatively in an ultrasonic bath with alcohol, this makes sense if you have to clean several boards at the same time without spending a lot of time, for hobby use this is not necessary.

After cleaning, the circuit board should be completely clean and free of grease so that the new solder joints hold perfectly and there are no false signals due to minimal currents.

Step 6: Insert new Hallsticks

Now you can carefully insert the new Hallsticks into the holes. Make sure that the pins are straight and sit correctly. Sometimes the pins are slightly bent, in which case you will need to carefully straighten them with tweezers or your fingers.

Press the sticks down firmly so that they sit firmly on the board. Make sure that they really sit perfectly on the board, Hall sticks that are soldered in slightly crooked cannot be calibrated as well later and may be inaccurate.

Check that the black buttons on the underside of the sticks are straight and correctly positioned by pressing them lightly.

Step 7: Solder on the Hallsticks

When soldering on the new sticks, we recommend first fixing the corners of the sticks with a thick soldering tip. This ensures that the sticks hold securely and do not fall out.

- Heat the corners of the solder joints and apply some solder.

- You can also apply some solder directly to the soldering points for the triggers and vibration motors, which will make it easier to solder the cables on later.

- Then change to a thinner soldering tip (1.5mm diameter) and solder the small soldering points carefully.

After soldering, you should clean the circuit board again with alcohol to remove all residues.

Step 8: Function test and first calibration

Before you reinstall the circuit board in the controller, you should test the function of the new reverb sticks.

Connect the controller with the battery plugged in to your PC via USB and use our free online controller tester to check and calibrate the sticks.

Check the following points:

- Whether the sticks are centered after calibration (values close to zero, e.g. 0.05 or lower)

- Whether the sticks can be moved in all directions without tearing out

- Whether L3 and R3 can be pressed evenly and also release when pressed.

Step 9: Reassemble the controller

If the sticks work well in the test, you can reinsert the circuit board into the controller.

Carefully reassemble the controller and tighten all screws. Make sure that all cable connections are correctly seated and that nothing is jammed.

Step 10: Final calibration with our gamepad calibrator software

For the perfect setting, we recommend using our free Gamepad Calibrator/Tester. This software allows you to precisely set the embroidery center and range.

This is how calibration works:

- Start the software and press “Connect”. You must use Google Chrome, other browsers are currently not supported.

- Select your controller and connect it.

- First calibrate the embroidery center (“Stick Center”). You can only test this temporarily if everything is OK: tick the box to save the setting permanently and press “Start”.

- Now move both sticks slowly to the top left, release, continue to the top right, release, then to the bottom left and release.

- Check whether the sticks are now perfectly centered (values close to zero).

- Then calibrate the range (“Stick Range”). Slowly turn the analog sticks once or twice in a circle and save the setting.

- The sticks should now run smoothly on a circle, not on a square.

If you have no experience with the software, you can first perform a temporary calibration before making the permanent setting. You can then reset and restart at any time.

Tips and tricks for Hallstick installation and fixing stick drift

- Always use a high-quality soldering iron with sufficient power (at least 80 watts, preferably 100-120 watts).

- Use our desoldering attachment for even heat distribution and fast desoldering. For commercial customers/custom controller companies who regularly carry out such conversions, we recommend the professional desoldering adapter as it saves a lot of time.

- Clean the circuit board carefully after desoldering so that no solder residue interferes with the new connections.

- Always calibrate the sticks after installation to ensure optimum precision and avoid stick drift.

- If you have problems with the calibration, check that the sticks are soldered properly and flat on the board and that the board is well cleaned.

More upgrades for your PS5 controller

If you want to upgrade your PS5 controller even further, take a look at our PS5 custom controller products:

- PS5 Custom Controller Configurator – Create your individual PS5 controller with different colors, paddles and upgrades.

- Configure PS5 Remapper & Paddle Set – PS5 DIY Kit for self-installation of paddles and many other modifications.

- PS5 case configurator – Design the complete PS5 case of your controller with many designs and colors.

FAQ – Frequently asked questions about Hallstick installation and fixing stick drift

What are Hallsticks and why are they better than conventional analog sticks?

Hallsticks use Hall effect technology, in which magnetic fields are used to determine position instead of mechanical contacts. This results in no friction, which leads to less wear and a significantly longer service life. They are also more precise and almost completely prevent stick drift.

What tools do I need for Hallstick installation?

You will need a powerful soldering iron (at least 80 watts), a desoldering tip or our desoldering attachment especially for analog sticks, soldering paste with a low melting temperature (approx. 181 °C), a desoldering pump, a platinum holder and cleaning materials such as alcohol and a toothbrush.

Can I install the Hallstick myself, even if I have little experience?

Yes, with the right instructions and the right tools, installation is also feasible for hobby modders. It is important to work carefully, not to overheat the circuit board and to calibrate the sticks well after installation.

How can I tell if my sticks have stick drift?

Stick drift occurs when the character or camera moves by itself in the game even though you are not touching the stick. You can fix this problem permanently with Hallsticks.

How do I calibrate the sticks correctly after installation?

Use our calibration software, Gamepad Calibrator, to set the stick center and range. Follow the steps: Calibrate stick center, then calibrate stick range and save the settings. You can also test your controllers directly there.

Can I also use Hallsticks for PS4 controllers?

Yes, Hallsticks are compatible with PS4 and PS5 controllers. Just make sure you buy the right models for your controller and follow the instructions carefully.

Where can I buy the reverb sticks and accessories I need?

We offer all the Hallsticks, solder paste, desoldering attachments and other tools you need at bitro.de. There you will also find detailed product descriptions and tutorials.

Conclusion

With the Hallstick installation, you can upgrade your PS4 or PS5 controller yourself to eliminate stick drift and enjoy permanently precise analog sticks with anti-stick drift technology. The combination of high-quality tools, special solder paste and the right calibration makes the conversion easy and safe.

Use our step-by-step guide and the recommended products to make your controller fit for many more gaming sessions. For even more individualization, we recommend our custom controller configurators and modifications to make your controller not only technically but also visually unique.

If this is all too complicated for you, you can also simply send us your controller via our conversion service. We are very experienced in rebuilding and repairing PS4 & PS5 controllers and can easily do this for you. Click here for our controller conversion service.

Good luck with the analog stick repair and have even more fun playing!